OF COURSE I dabble in electronics. What self respecting geek doesn't? It's been a long haul though - for many years I had a less than stellar success ratio with circuits. Frankly, I had pretty much given up. I even had one of those "1001 projects with electronics" toys - but I only ever attempted about 100 of them, and maybe got 20 to work properly. It never really excited me too much - making a "real AM radio" ( why? I had an AM radio - I wanted an FM radio...) or a "lie detector" ( "Hey Pat! Are you stupid? " "NO!" "BEEEEEEEP" "HA HA PAT'S STUPID").... yeah, tons o' fun.... sorry Pat.

OF COURSE I dabble in electronics. What self respecting geek doesn't? It's been a long haul though - for many years I had a less than stellar success ratio with circuits. Frankly, I had pretty much given up. I even had one of those "1001 projects with electronics" toys - but I only ever attempted about 100 of them, and maybe got 20 to work properly. It never really excited me too much - making a "real AM radio" ( why? I had an AM radio - I wanted an FM radio...) or a "lie detector" ( "Hey Pat! Are you stupid? " "NO!" "BEEEEEEEP" "HA HA PAT'S STUPID").... yeah, tons o' fun.... sorry Pat.Anyway, fast forward to when I had trains. "Make you own Electronic Speed Control", "A Computerized Turnout System", "Home made DCC for your trains".... not so much. Most of the projects I couldn't even begin to source out parts - "Radio Shack" really didn't have the inventory necessary for most of them, and as I recall, they were pretty complicated. More for the retired electrical engineer than a geek with a $10 soldering iron.

Nowadays I like to muck about with microprocessors. Definitely a LOT easier when a computer program does 90% of the work. And most of the parts you can get at Radio Shack.

Of course, the hard part is assembling the damn things. I've used prototyping boards, but I hate having to route wires everywhere. And up until now, PCBs were a thing you could only get done professionally at a ridiculous cost. Well, ridiculous if you only want the one board for a hobby project...

But now....I can do it myself ( to borrow a phrase from #2 )

1. Design the circuit: I use something called PCB Wizard. It assumes you've got a lot of basic parts and can suss out a circuit schematic. It also designs the board and the traces for you - which is one of those things that you previously needed an engineering degree to do...

2. Print the circuit using a laser printer on glossy magazine paper. I like Teen People magazine. Probably just a coincidence, but I get some really great boards with this ( I got it from the Library discard pile, thank you very much)

3. Use the Graphics Departments heat press to iron the laser printer toner onto copper PC board. We have TONS of old copper boards around, leftover from the days when we had a pretty good electronics program.

4. Remove the paper. I like to soak the boards in hot soapy water - the paper peels right off, leaving the toner on the board to act as a resist to the etchant.

5. Etch the boards. I used to use ferric chloride, which you can get at any electronics store. But the stuff is nasty and you can't pour it down the drain. Also, you can't see through it to see how your boards are doing. Now I use a special brew of hydrochloric acid and hydrogen peroxide, which turns a lovely emerald green while it's doing its work. Also nasty, but easy to clean up spills with baking soda and water.

6. Drill the boards. Again, leftovers from the electronics department yield a nice drill press and a few dozen drill bits.

I've made sets of boards for my Physics 12 class to learn about circuits, some demonstration projects, a pre-amp for my Laser Show and now I'm working on a class set of microcontroller boards to teach physical computing.

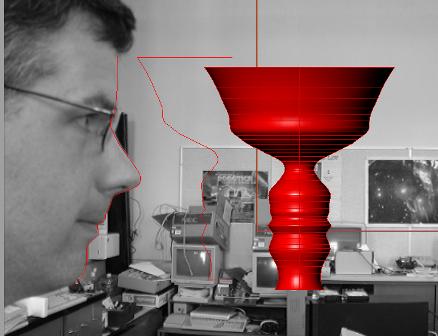

And today I etched my first double sided board ( see above ). I am teh ROXXOR!

No comments:

Post a Comment